about us

WHO

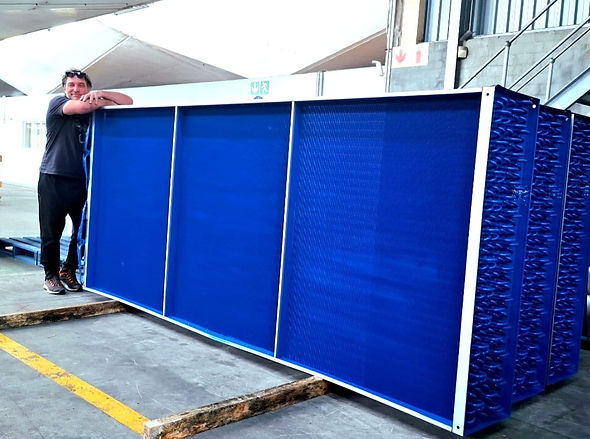

ProTEQ Corrosion Protection Treatment ensures maximum protection for condenser and evaporator coils with our tailor-made urethane technology

WHY

Simply corrosion, in the form of atmospheric marine conditions, industrial pollutants and vehicle emissions lead to wasted equipment, wasted energy and wasted money. Copper and aluminum components, as well as covering panels are subjected to inevitable corrosion.

Consider the positives of our coating:

-

Longer lasting equipment

-

Electrcity and time saving

-

Consistent performance of unit

-

Financial

HOW

Our systematic application process:

-

Remove panels, clean and comb the coil

-

Dry and prepare for spraying

-

Prime with Aluminum-based application

-

Apply multiple coats of ProTEQ Treatment

-

Dry and cure

-

Re-assemble panels

WHAT

A unique, resilient and durable application that protects without hampering the performance of your unit.

-

High strength performance

-

UV, abrasion, chemical and weather resistant

-

Flexible, resists chalking and brittleness

-

Quick drying and rapid hardness development

-

Our products conform to the EU environmental standard and is EEC Reach compliant

-

ASTM tested and approved

.jpeg)